UV Systems: What Are They and Why Do We Use Them?

To follow up on our latest post about biosecurity, we will continue now and dive deeper into the world of UV sterilizers. UV systems are probably the most common form of process water disinfection that we find in our travels to various aquaculture facilities. The reasons for this are quite simple as they are easy to install, simple to operate, and can be added to new or existing operations.

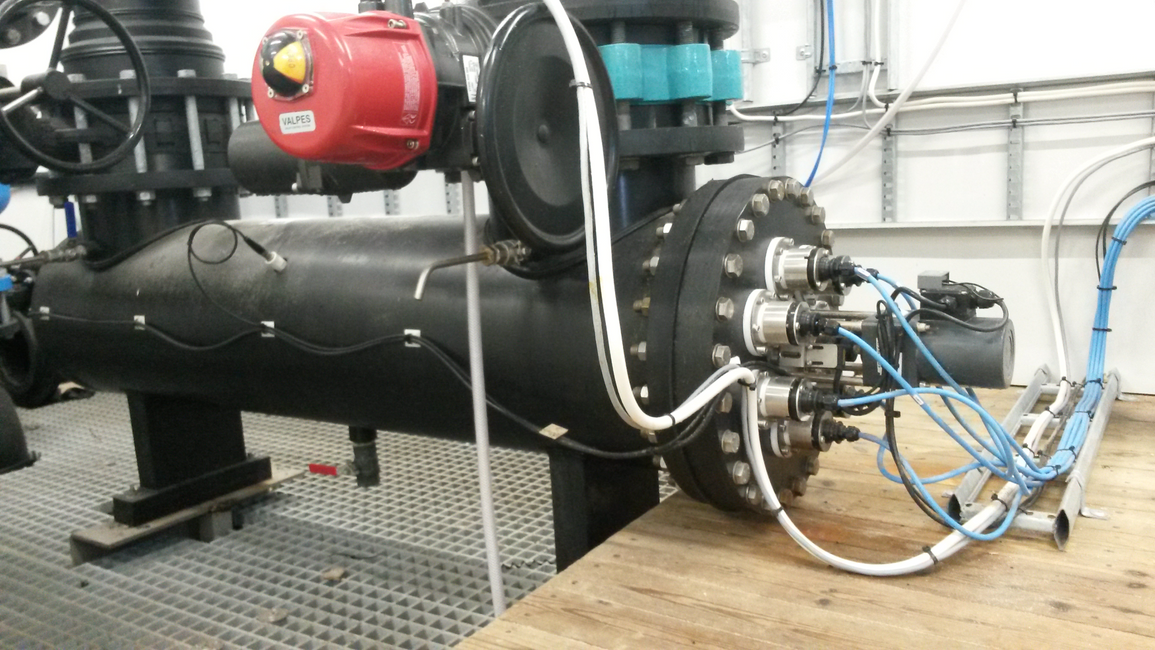

Before we get into the benefits of UV sterilization, we should first consider how they operate so we can better understand the uses and limitations of this technology. The most basic way to describe their operation is that water is passed through a vessel containing one or more light bulbs. Instead of putting off visible light, like your light bulbs at home, UV systems emit light in the ultraviolet spectrum. At very specific wavelengths of light (specifically 254 nanometers for our applications), the light causes an interesting effect on cells. The UV light does not actually kill any organism, but rather damages the DNA of the cell, rendering it unable to reproduce. By causing a double bond between two adjacent bases, the cell is unable to reproduce it’s DNA and thus the organism perishes shortly thereafter.

UV sterilizers provide a dual benefit of improving water clarity and quality, while at the same time reducing populations of pathogens within the system. We typically see UV systems installed on recirculating growout, nursery, and hatchery systems, as well as on incoming and outgoing water supplies for aquaculture facilities. On inlet water, the main purpose of these systems is to remove any potential pathogens before they enter the facility. In recirculating systems, UVs prevent water cloudiness due to bacterial blooms and prevent opportunistic pathogens from replicating and growing in population. This is very important, because in the high stocking density environments in which we operate, it is easy for disease to spread once introduced. Many systems with chronic disease problems are cured once a UV is added and the owner wonders why they didn’t add one years before!

UV Systems are effective against a wide variety of pathogens, including those most commonly seen in aquaculture: viruses, bacteria, and protozoa. To ensure proper sterilization of a system, it is important to size a UV system properly. There are three main criteria that we use to size a UV system. First is water flow rate. This determines the contact time of the UV light with each gallon of water passing through the system. Second is UV transmittance of the water. UV transmittance (UVT) refers to the ability of UV light to pass through water. While this may sound like turbidity to many people, clear water can actually have a very low UVT value due to dissolved metals which act like sponges, soaking up the available UV light and causing UVs to not function properly. The final value we look at for sizing is required UV dose. Each pathogen has a different cellular structure, and as such, some require a higher or lower UV dose to effectively destroy the organism. The “standard” UV dose of 30 mJ/cm2 is acceptable for many types of bacteria, but larger organisms like Cryptocaryon irritans (white spot) may require 280 mJ/cm2, and some may require even more! As such, it is important to always share proper information with whoever may be sizing your UV system, as undersizing on any of these parameters will cause the UV to not function as desired. For more information on UV systems and how they can benefit your facility, please reach out to any of our Global Aquaculture Supply representatives and we will be glad to help you!